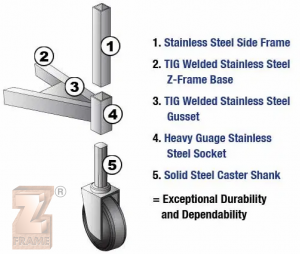

The Z-Frame® Advantage

Z-FRAME® Racks are built to withstand abuse.

- Stainless steel TIG-welded bottom frame provides the rack with the durability to prevent bending. Unlike aluminum racks, Z-FRAME® Racks are virtually indestructible.

- Heavy gauge stainless steel sockets provide additional support to the uprights and casters

- The polyurethane dual precision bearing swivel caster offers extended durability and smooth mobility, even when racks are nested

- Z-FRAME® Racks Quick Change Caster System allows for fast and easy caster changes

Z-FRAME® Racks are designed to easily nest out of the way when not in use. They take up less space than conventional racks, creating a safer, cleaner, and more efficient workspace.

Z-FRAME® Racks are perfect for many commercial applications, including materials handling, central commissary, and extreme duty, and are manufactured to precise specifications using our portfolio of patented and “road tested” features. They can also be custom-built based on your needs and requirements.

Z-FRAME® Racks are made in the USA by experienced and highly skilled tradespeople.

The TIG Welding Advantage

When it comes to building stainless steel or other metal equipment, manufacturers have several welding options to choose from. Since 1975, we have chosen to build our racks and equipment using Tungsten Inert Gas (TIG) welding because of the following benefits:

- TIG produces strong, precise, and aesthetically pleasing welds with few defects or imperfections

- TIG is superior for stainless steel equipment

- TIG is the cleanest welding process with fewer impurities in the materials

- TIG is specified by the aerospace and pharmaceutical industries

- TIG requires highly specialized training to achieve proper precision and accuracy

TIG Welding

Why doesn’t every manufacturer use TIG welding? For most companies, it comes down to cost. Other methods, such as Metal Inert Gas (MIG) and stick welding, are more cost-effective: the materials are cheaper, the welding process is faster, and the operators don’t have to be highly trained (and paid accordingly).

For us, the choice was simple: To build superior products that outperform and outlast the competition, we need to use the best materials and methods available and employ the most qualified tradespeople in the business.

For 45 years, M&E has focused on designing and manufacturing the highest-quality professional equipment and providing extraordinary customer service. We stand by (and sometimes on) our products.